Please be aware we use cookies to make your experience better. A cookie is a piece of data stored on a visitor's hard drive to help us improve your access and identify repeat visitors. Cookies can also enable us to track and target the interests of our users to enhance the experience on our site. Usage of a cookie is in no way linked to any personally identifiable non-public information. Learn more.

Electric Actuators & Screw Driven Stages

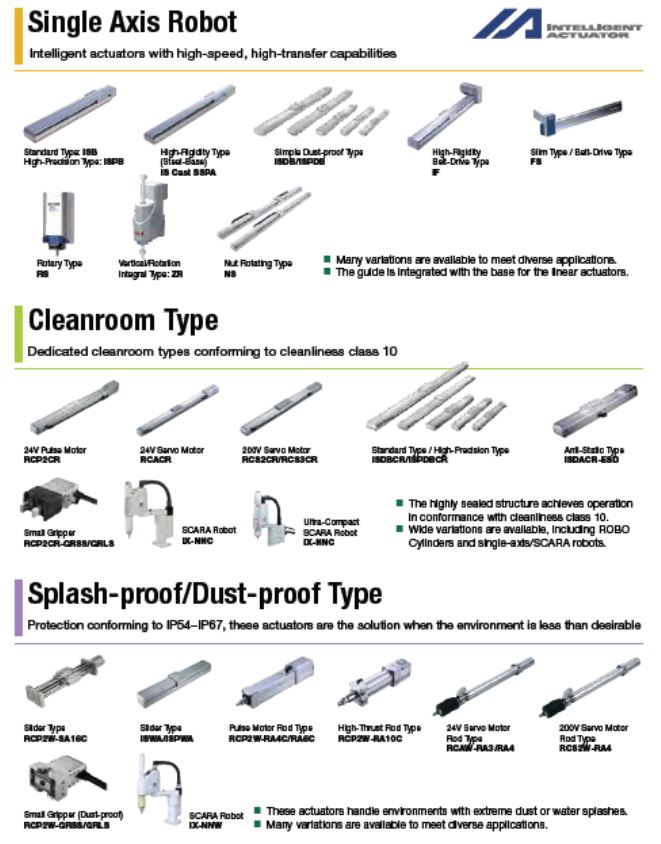

Founded in Japan in 1976, with American headquarters established in 1989, IAI designs, manufactures, and markets a complete line of motion control systems, including electric actuators, motorized linear actuators, and motorized screw driven linear stages. As the established world leader in linear electric actuators and low cost, high performance SCARA robots, they provide over half of all linear actuators sold in Japan and are a leading source of advanced plug & play automation throughout North America and the world.

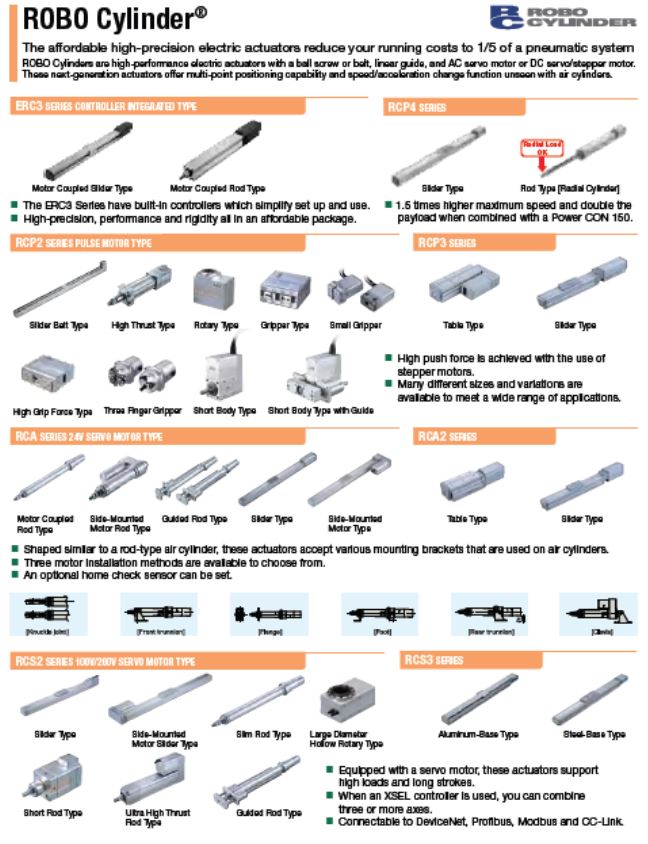

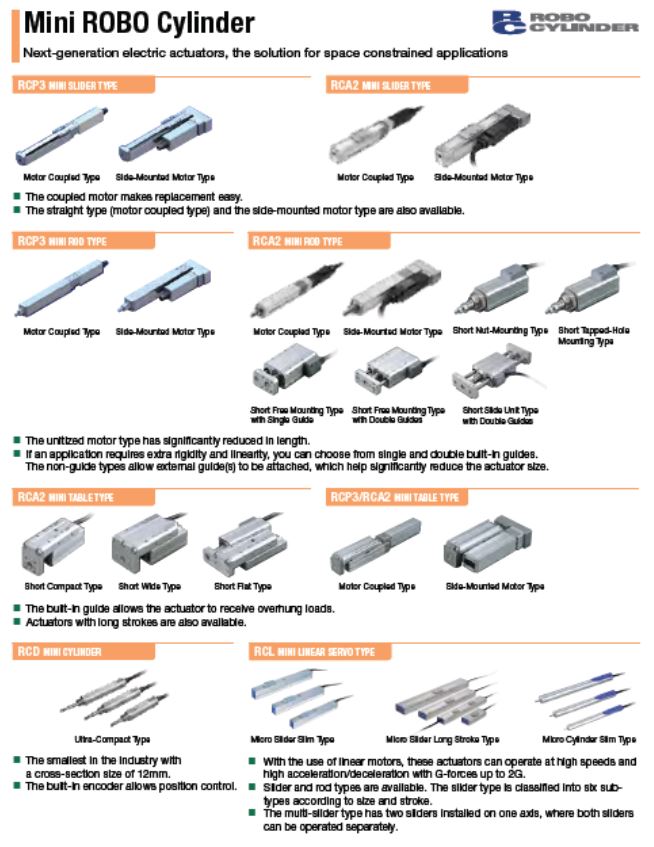

One of IAI's product lines we are proud to offer is the Programmable ROBO Cylinder® electric actuator is a flexible, intelligent, and economical, ballscrew linear actuator from Intelligent Actuator. IAI’s Programmable ROBO Cylinders combine high moment load capacity with high precision capability producing a positioning actuator with exceptional torsional rigidity and reliability.

- View a 4 minute YouTube video on the features and benefits of the Robo Cylinder: Robo Cylinder Features & Benefits YouTube Video .

- View a 13 minute YouTube video illustrating the Robo Cylinder Family: Robo Cylinder Family YouTube Video .

The ROBO Cylinder® Features:

- Multiple Positioning – With the ROBO Cylinder, you can achieve positioning of up to 1,500 points and a repeatability of ±0.02mm. Benefit: Use one assembly line to produce a variety of products and achieve higher quality production with a repeatability of ±0.02mm.

- Push and Hold – The push force (pressing force) can be easily adjusted by changing the position data values. The push force can also be set to constant. This function is perfectly suited for press fit applications and parts holding. Benefit: Push and hold hard/soft materials equally well without damaging your product. Great for press fit and clamping applications.

- Acceleration/Deceleration Settings – Set the acceleration and deceleration independently on the ROBO Cylinder. Benefit: Improve cycle time and drastically reduce part defects. Produce more in less time.

- Zone Output – Output a signal when the ROBO Cylinder reaches a preset range, all without a need for external sensors. The zone output function allows the ROBO Cylinder to shorten cycle time, output a danger area signal and can be used for a variety of applications. Benefit: Save yourself time, money and effort of adding external cumbersome sensors.

- Pause Input – Unlike pneumatic systems, ROBO Cylinders are capable of stopping at any point of the stroke during operation. Benefit: This allows for collision prevention and greater safety for operators and equipment.

- Incremental/Decremental Moves – When performing continuous movement with uniform pitch, repetitive movement is possible with data of a single position. Benefit: This function can speed up programming and reduce I/O count.

- Speed Change During Movement – Speed can be changed easily during movement. Easily set a position band and change your speed during movement. Benefit - Improve cycle time and minimize product defects, resulting in higher quality production and ROI.

- Energy Efficient – ROBO Cylinders are highly energy efficient and will cut running costs, giving you substantial ROI. Functions such as Full Servo Control Mode, and Automatic Servo Off Mode, further improves energy efficiency making ROBO Cylinder the choice for discerning automation engineers all over the world.

- Longer Life = Greater ROI - In addition to less product defects, operator safety, shorter cycle times, energy efficiency and higher quality production, ROBO Cylinder electric actuators last 10 times longer than similar air cylinders.

- Quiet Operation - Are you tired of the ear-splitting noise generated by pneumatic systems? ROBO Cylinder electric actuators offer quiet operation without the need for mufflers.